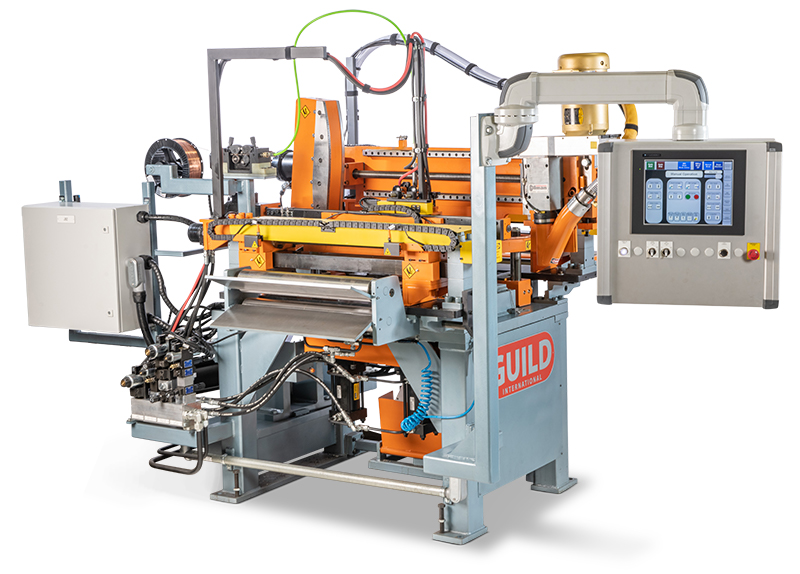

The Guild International ME Zipwelder is on the forefront of strip joining technology and utilizes the latest welding methods available including TIG, MIG, Plasma and solid-state laser beam. The ME Zipwelder is used where extremely fast, consistent, high quality welds are necessary on materials ranging from 0.006” – 0.750” thick, up to 60” wide. The ME Zipwelder is being utilized in a variety of strip processing lines in worldwide applications on such as tube and pipe mills, roll forming, stamping, galvanizing, slitting, and annealing and pickling lines.

A combined MIG/TIG torch expands your range of processible materials, providing flexibility to weld a wide variety of materials and thicknesses.

The hydraulic, double-cut shear allows both coil ends to be sheared simultaneously, reducing cycle time, while the design allows for automatic scrap evacuation and collection. Both coil ends are initially clamped, simultaneously sheared, then automatically indexed to the proper welding position. Guild’s exclusive adjustable weld gap control permits the operator to pre-select the correct gap for the material being welded. The automatic, variable speed welding torch carriage is integrated into the clamp, guaranteeing accurate torch tracking with the weld seam.

The ME Zipwelder can be customized to include both MIG and TIG welding capabilities on one machine, on-board weld bead milling, and semi- or fully-automatic operation to reduce operator involvement and increase mill up time. Save time and money while increasing worker safety with a Guild ME Zipwelder on any strip processing line.