The VE-10 Shearwelder is a low cost method to join coil ends together up to 10″ wide by .075″ thick on stamping lines, roll form lines, and tube mills.

VE-10 SHEARWELDER™ EXCLUSIVE FEATURES:

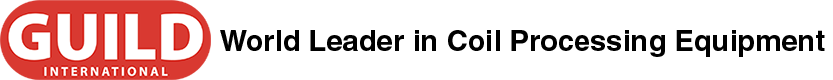

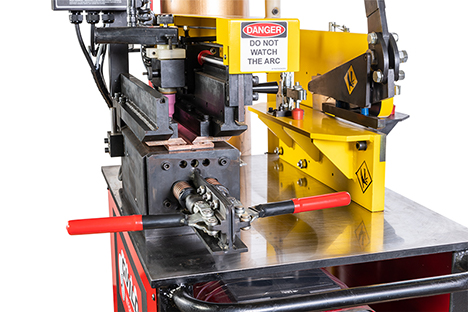

The VE-10 Shearwelder is available for use in semi-automatic and automatic working conditions. Available in normal, large size, and portable versions, these shear welders are actually precise thin gauge machines, ideally suited for use in roll form lines, stamping presses, coil mill, and small tube mills. The machine consists of a small shear table, a work-holding device, an upper and lower blade, as well as a gauging device. VE-10 Shear Welders are the most well-suited for shearing and welding purposes and are ideally used to cut down material of any thickness and width as required by the application. The VE-10 allows the use of multiple line cutting system regardless of strip flow, thus helping to bring down the cost incurred for welding. VE-10 Shear Welders are ideally suited for shearing coils.

Standard items on the VE-10 Shearwelder include an automatic, built-in gauge bar at the weld station, a machine mounted work light, and one-button, automatic weld cycle. The VE-10 Shearwelder is equipped with a manual lever-arm shear and manual clamping. The shear gives precision edges for the fit up while the manual clamping allows for accurate positioning of thin gauge strips. Also standard on the VE-10 Shearwelder is a DC variable speed carriage and 225-amp Lincoln Electric Square Wave weld rectifier.

Why Choose Guild

VE-10 Shear Welders are the most well-suited for shearing and welding purposes and are ideally used to cut down material of any thickness and width as per the requirement of the customers.

VE-10 Shearwelders follow on the simple methodology, where a punch is used to push a work-piece against a fixed die. Although the thickness is dependent on the material, VE-10 Shear Welders have the capability to perfectly measure and adjust the point where the cutting action should take with respect to blade movement. One of most widely used Shear Welders, the VE-10 Shear Welders comes with automatic built-in gauge bar, a machine mounted work light, and 1 button automatic weld cycle. The VE-10 Shear Welders are also equipped with a manual lever-arm shear and manual clamping system, which allows better precision edge welding, while the manual clamping system helps in getting correct positioning for the thin gauge strips. Also available as standard feature with the VE-10 Shear Welders is a DC variable speed carriage, as well as a 225-amp Lincoln Electric Square Wave weld rectifier. A variety of Shear Welders are available for use in joining coil ends together that are up to 10-inch wide and .075-inch thick. As these shear welders come in a wheeled base, this allows the welders to be moved from one place to another place with non problematic issue.

The VE-10 Shearwelder uses the straight shearing process for shearing coils. The work-holding device holds the work piece in place, not allowing it to move or buckle while under pressure. The upper and lower blades of Shear Welders actually do the cutting, while the gauging device is used to ensure that the work-piece is cut where it should be. As with the need to make machine work automated, many Shear Welder machines are available in automated as well as manual operating system. As a welding and cutting equipment these Shear Welder machines come with standard features such as pneumatic double blades for effective precision cutting, precise motor and switch with stable and precise welding gun movement, automatic centralized pneumatic copper mold clamp for accurate and rapid function, inverter DC TIG welder, compact construction design, furniture/decoration round/square tube makers, window slide/ceiling roll-forming rack makers, and silic chip and electronic parts pressing continuous press makers. The shear welders can also be designed as per the requirement and specification of the customers.