Click images for larger view.

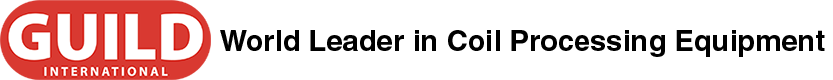

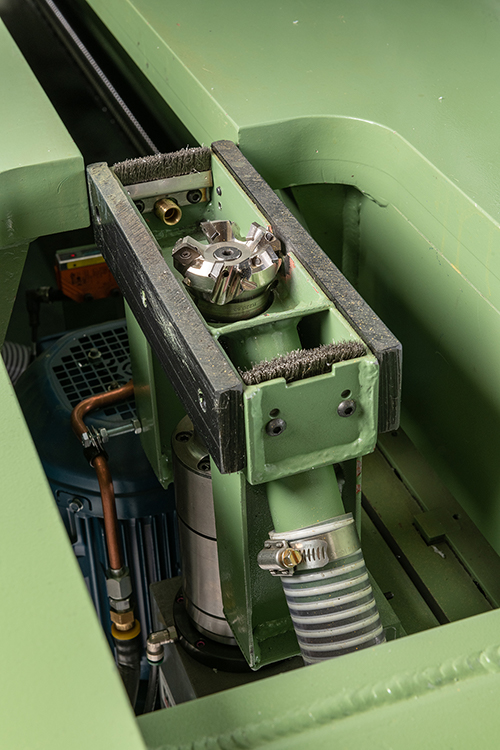

The Guild Top and Bottom Bead Milling Machine is a must for any production line with welding units being utilized. Our milling machine is perfect for removing any excess weld bead material from the top and bottom of the welded joint. This unit includes both upper and lower milling heads, drive assembly, strip clamp, and a chip collector system, all supported by the main frame. The complete assembly rides on wheels and can be positioned by hydraulic cylinder so that the milling assemblies are in the proper position for weld bead removal.

Our milling machine is perfect for removing any excess weld bead material from the top and bottom of the welded joint.

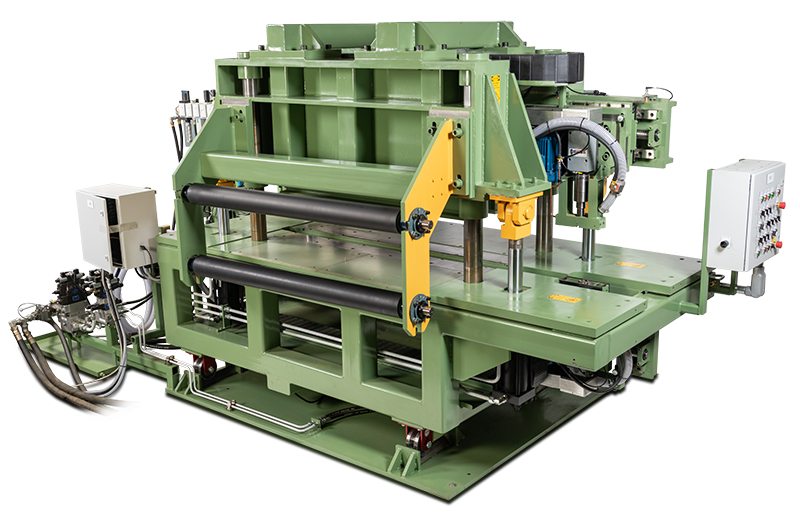

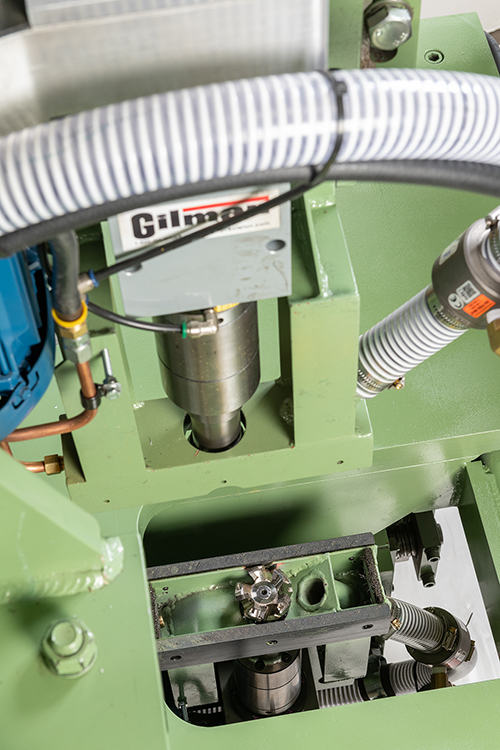

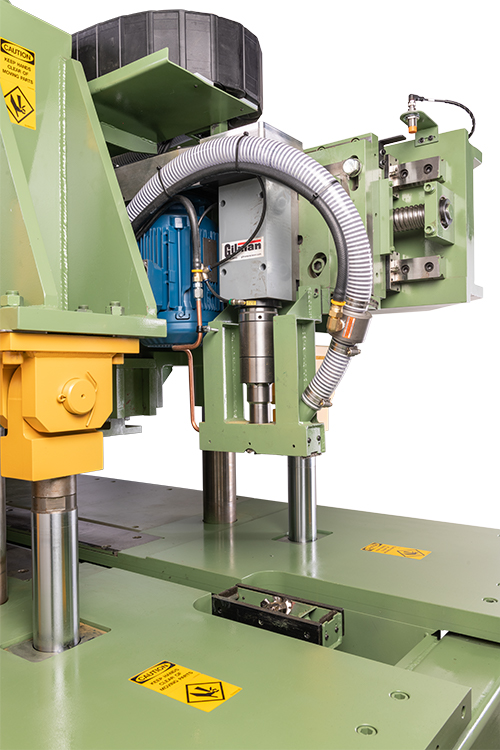

The spindles are retracted and raised during line run. Guild uses Setco B070 high end Sentry precision spindles. The spindles are powered by individual A.C. motors, and the spindle traverse is by a common variable speed A.C. drive system. The upper head is positioned vertically on slides by electric motor for final positioning prior to the milling operation.

The upper strip clamp is made of a four (4) post, heavy-duty design. One clamp contains both strip ends while the upper milling device is mounted off this clamp. The center of the clamp is slotted to permit passage of the upper milling cutter. Within this main upper clamp are separate sub-clamps which are used to clamp the thinner of the two strip ends. These sub-clamps are operated through a wedge and hydraulic cylinder. Included in the secondary clamps are sensors that are used to determine the clamps final position. This information is then sent to the machine control device so that the upper milling head is properly positioned prior to the milling operation.

This machine is designed to mill either top only, bottom only, or both top and bottom, depending on the selection by the operator. The two strip ends do not need to be the same thickness for this unit to operate properly. However, maximum deviation between strip thicknesses should not exceed 2.0mm.

A vacuum-type chip removal system is provided to collect debris from both the top and bottom of the strip surfaces. And a weld detector device is provided to send a signal to the line control devices to stop the weld in the area of the milling machine.