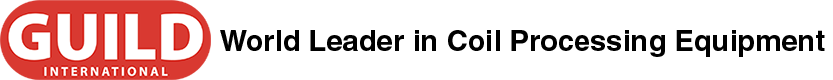

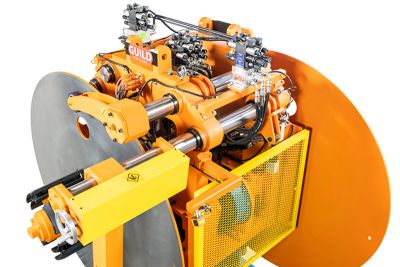

The Guild UNC Uncoiler is a machine that is used to hold the coils straight to allow the gradual unwind of the coils during press operations. Uncoilers are available in a number of variations, but the most frequently used samples are the single and double ended arm units. The machines are meant for use in heavy duty fabricated steel making, and are designed for use in different types of processing lines including roll form lines to high speed tube and pipe mills. Most of the times the uncoilers that are mostly used in steelmaking are available in the sizes of 15,000 lb single and 25,000 lb double. However there are a variety of uncoilers available in sizes ranging from 3,000 lb – 40,000 lb.

The UNC Uncoiler is available in both single and double arm units.

These machines feature heavy duty fabricated steel construction and are designed to operate on many different types of processing lines including roll form lines to high speed tube and pipe mills. The uncoilers are available with many options to fit your specific application.

Uncoilers are available with a variety of customized features, however the standard features available with uncoilers are 12″ traversing base, outboard coil retainers, speed funnels, shearwelders and accumulators, hold down arms and snubbers, feed-up and rewinders, powered hydraulic rotation system, hydraulic expansion, manual/hydraulic expansion of mandrel, wedge/link type expansion, AC variable speed drives, hydraulic threading drives, quick release narrow coil keepers, loop controls alloy steel main shaft, 4-segment drum, coil joining – tube mill entry systems, 0.500″ thick steel back plate, large air brakes, hydraulic cylinders for drum expansion, and 2 slots per back plate for “C” hook loading.

UNC Uncoiler™

Why Choose Guild

Some of the varieties of uncoilers available include uncoiler-decoiler with capacities ranging from 3 tons to 20 tons and width range of 200mm to 1600mm. These uncoilers come with a “bearing tube” with dual cup, and cone Timken bearings as well as a heavy duty cabinet base. Depending on applications these unicoliers are available in both motorized and pull-off type reel varieties. These unicoilers are available in standard single-end configurations, however double-ended configurations are also available that can help improve production efficiency by lowering coil changeover time. Some of the standard features available include traveling reels with automatic centering functions, electric eye loop control system and pneumatic control system, feed and straightener rolls with a hard chrome plating, outgoing catenary, hold down arm device, reference indicator adjuster, outgoing catenary to assist and support the material, cluster gear set to maximize transmission of horse power, and many others.

Another example of uncoilers is the Fin Line Uncoiler that has been specifically designed to supply press with raw materials (coils) needed for production of a fin. Fin Line Uncoiler supplies a loop of coils to the lubrication system before entering the fin die. The Fin Line Uncoilers can be driven using different type of motors. The specialty of Fin Line Uncoilers is a limit and a stock fault switch for controlling the stock loop that helps prevent any loss of progression in fin press. These limit switches located near the stock slide screen of the uncoilers, have been installed to signal a clutch time when to engage and when to disengage operation. As with other machines these unicoilers are also available in custom designed forms as per the requirement and specification of the customers.