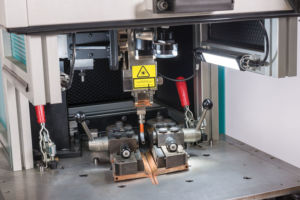

The LHMA Laser Welder™ is designed and engineered to be one of the most technically advanced laser welders on the market. It can create complete edge-to-edge welds without the need for start and stop tabs, on strip as thin as .003,” something that until now, has not been available.

LHMA LASER WELDER EXCLUSIVE FEATURES:

The Guild LHMA Laser Welder utilizes an American built fiber laser to deliver the necessary energy for welding via a fiber optic cable connected to a focusing head. The focusing head concentrates the energy to a very fine spot to achieve weld results never before possible on steel, stainless steel, copper and brass alloys and aluminum. This system is designed for use on either start/stop lines or continuous lines such as:

- Traverse Wind

- Cable Lines

- Stamping Lines

- Specialty Tube

- Coil Buildup

- Thin Strip Lines

One of the most technically-advanced laser welders on the market

Why Choose Guild

The LHMA Laser Welder includes a camera and large HMI touchscreen allowing the operator to view the strip fit-up prior to welding. In just 2 minutes, the process of shearing, aligning, and welding the two coil ends is complete.

Weld schedules can be stored for quick retrieval and the parameters are easily set with the HMI touchscreen. An interlocked safety enclosure provides the required safety for the operator.

For customers interested in this cutting-edge technology, Guild International maintains a fully operational LHMA Laser Welder in our facility to offer sample welds on customer specified material.

Save time and money while increasing worker safety with a Guild Laser Welder on your strip processing line.