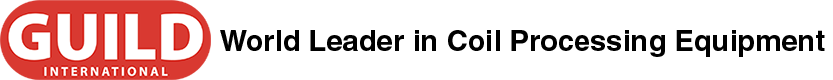

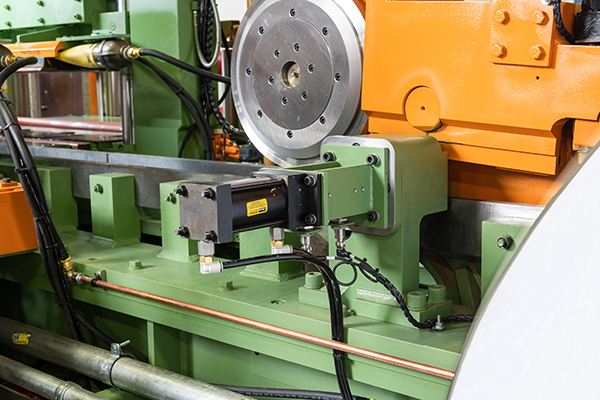

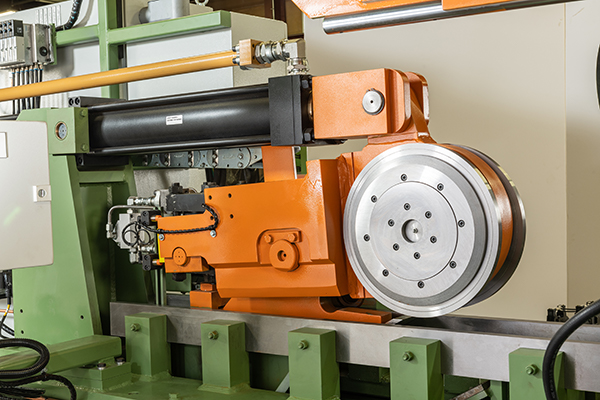

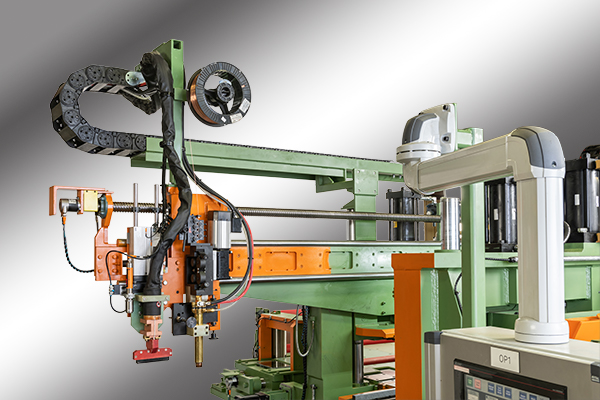

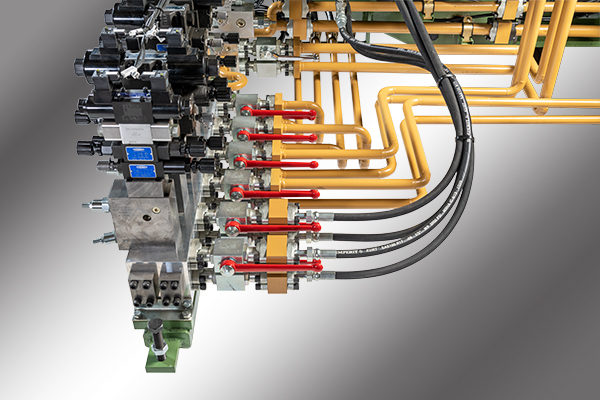

The RCM Zipwelder™ is engineered to be the most technically advanced shearwelder available. This fully automatic welding machine reduces operator involvement and increases mill uptime by reducing weld failure.

RCM ZIPWELDER EXCLUSIVE FEATURES:

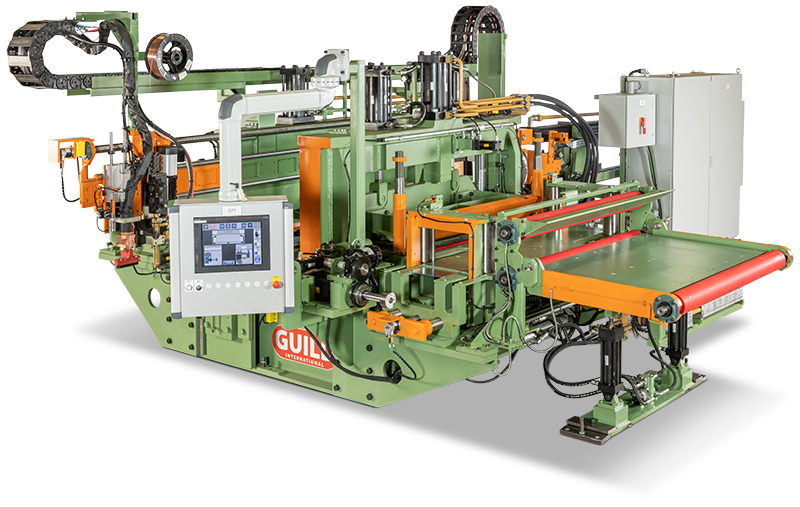

The RCM Zipwelder butt welds two coil ends together by using either TIG, MIG, PLASMA, or LASER welding. The RCM Zipwelder is designed for use on either start/stop or continuous lines such as:

- Pickling

- Rolling Mill

- Anneal & Pickle

- Tube/Pipe Mill

- Coil Prep

- Galvanizing

- Coil Buildup

- Others

Engineered to be the most technically advanced shearwelder available

Why Choose Guild

RCM Zipwelder machines are used on a wide range of weldable alloys including carbon steel, stainless steel, and aluminum.

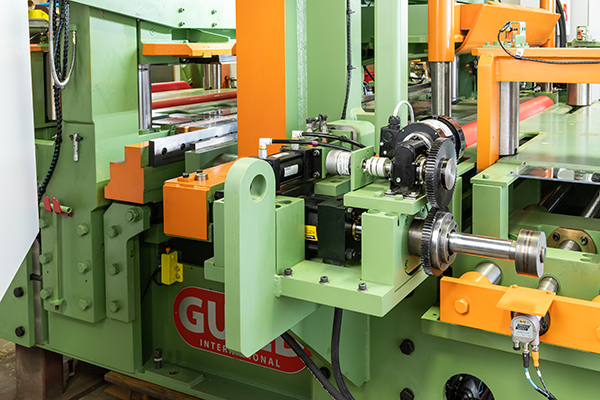

Depending on the process line requirement, the weld can be used as a transport weld, being removed at the exit end of the line, or it can be used for coil buildup. Butt welds created using this machine are usually as strong as the parent material.

These machines can shear and butt weld material ranging from about .45mm (0.018″) up to about 25mm(1″) thick and as wide as necessary. Recent machines have been used for strip up to 2,000mm (80″) wide. Any weldable material can be joined on these machines.