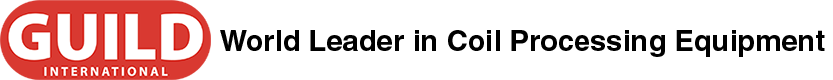

The Guild DMI Shearwelder™ is our economical choice for wide strip coil end joining. This machine is capable of handling strip up to .625″ thick and up to 85″ wide and creates a weld nearly as strong as the parent material. This semi-automatic shearwelder is specifically designed for applications such as annealing & pickling, rolling mill, coil prep, galvanizing, and tube & pipe mills where the coils are either too thick or too wide to be conveniently welded manually.

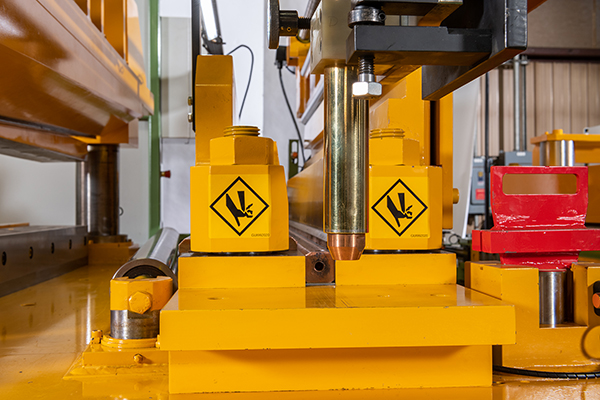

The DMI Shearwelders work well when operated alongside a Guild flattener, keeping the coils flat as it helps in proper operation of the shearwelders.

The DMI Shearwelders are machines that butt weld two (2) coil ends together by using either TIG, MIG, plasma, or laser welding. These machines are designed for use on either start/stop or continuous lines such as:

- Pickling

- Rolling Mill

- Anneal & Pickle

- Tube/Pipe Mill

- Coil Prep

- Galvanizing

- Coil Buildup

- Others

Choose the DMI Shearwelder for wide strip coil end joining

Why Choose Guild

DMI Shearwelders can shear and butt weld material ranging from about 0.060″ (1.50mm) up to about 1″ (25mm) thick, and as wide as necessary. Recent machines have been used for strip up to 85″ (2,150mm) wide. Any weldable material can be used on these machines. Since the coil ends must be flat for proper operation of these machines, the use of a Guild flattener is normally recommended. Depending on the process line requirement, the weld can be used as a transport weld, being removed at the exit end of the line, or it can be used for coil buildup. Butt welds created using this machine are usually nearly as strong as the parent material.

The DMI Shearwelder is ideally suited as a low-cost option meant for use in wide strip coil end joining.

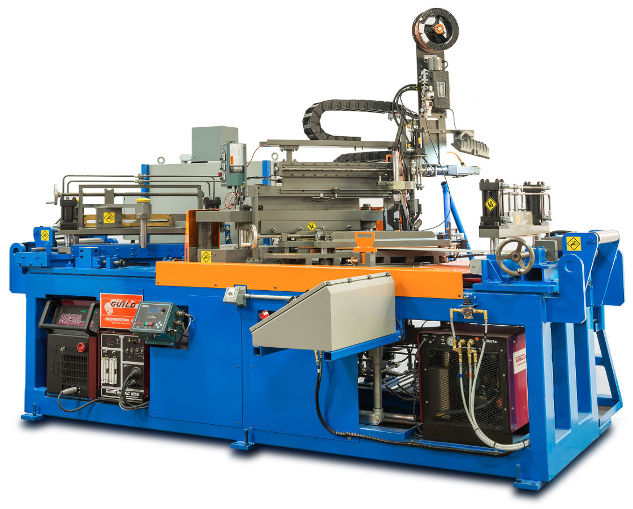

The DMI Shearwelders are capable of shearing strips with a thickness of up to .625-inch and up to 85-inch width. Available in a semi-automatic operation, the DMI Shearwelders have been specifically designed for use in situations where the coils are either excessively thick or wide that reduces the manual coil welding. The DMI Shearwelders that are capable of butt welding two coil ends make use of tungsten inert gas (TIG) welding, plasma welding, metallic inert gas (MIG) welding, as well as the laser beam welding methodologies.

The DMI Shearwelders are designed to provide a faster and accurate way to join coils on all types of strip processing lines. The DMI Shearwelders are ideally suited for use in either start/stop or continuous line processes such as pickling, rolling mill, coil prep, stamping, coil buildup, anneal & pickle, as well as galvanizing. The DMI Shearwelders are ideally suited for use with a wide range of weldable alloys such as stainless steel, carbon steel, aluminum as well as other types of alloy metals. Depending on the process line requirement, these machines can not only be used as a transport welding system that can be removed at the end of line, but can even be used for coil buildup process.

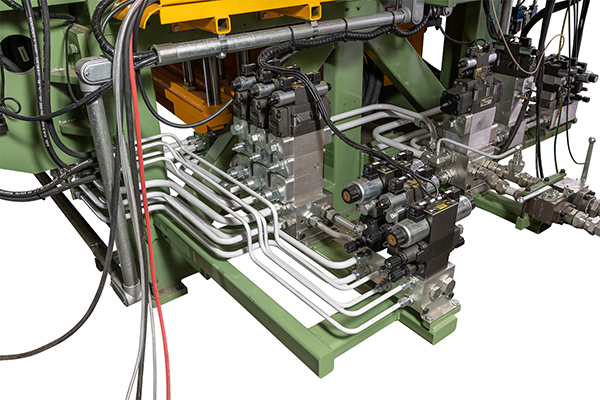

The uniqueness of a Guild DMI Shearwelder is that the gauge range for each application can be changed according to the requirements. The gauge range not just determines the rake angles, upper and lower shear blade clearances, but also tonnage capacity. These machines can also be designed as per the requirement and specifications provided by a customer. A shearwelder can sometimes be referred to as a coil end joiner, strip welder, end welder, coil splicer, or shear end welder. A shearwelder also can shear strip end, then butt weld coil strip. The DMI Shearwelders are also used to provide a smooth ductile weld, so that the newly joined coils can easily pass through a tube or pipe mill.