From the originator of the portable shearwelder, Guild offers the world’s most compact semi-automatic shearwelder. The PSA Portable Shearwelder is ideally suited for small tube mill, roll form lines, and stamping presses. The unique “C” frame portable design allows this machine to be used for multiple lines regardless of strip flow, cutting it’s already low justification cost in half or even thirds.

PSA PORTABLE SHEARWELDER EXCLUSIVE FEATURES:

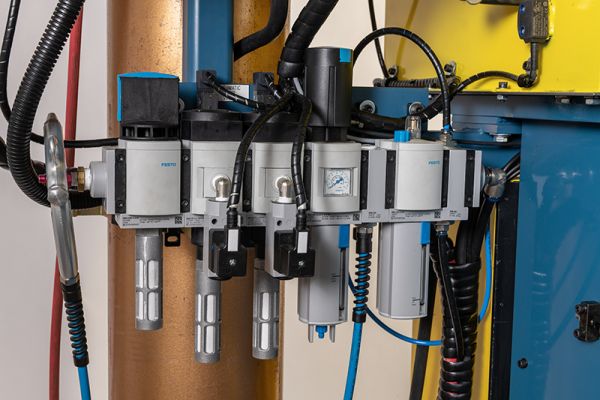

- A tungsten height gauge is provided that ensures proper setting of the tungsten electrode every time. For proper weld fit up, a built-in automatic gauge bar is provided with our patented split elevating backup bars. Other designs require the operator to manually insert the gauge bar properly and then remove it for every weld.

- Providing properly sized air cylinders for clamping provide over 200% more clamping force than others. These cylinders are mounted at the rear of the machine and preventing damage from strip and allowing the operator more work space during welding. Clamping and shearing actuation is by foot valves so the strip can be held with both hands by the operator.

- Solenoid-operated clamping bar makes for simple automatic torch traverse. (This feature eliminates the need for “Jog Forward” and “Jog Reverse” buttons, forward and reverses weld carriage motor relays, and weld start limit switch). Additionally, torch acceleration is instant and without slip.

- Pneumatic powered three-bladed shear for distortion free shearing with two (2) die spring loaded stripper pads to hold the strip during shearing for a straight cut.

- Automatic V.C.R. relay senses that the welding arc is correctly established before the welding carriage is allowed to travel. Fused disconnect is standard on all PSA control panels. Step-down transformer is also standard. Only one (1) electrical line is required. Quick change backup bars are provided. Only one screw at the front of the machine is required to remove each bar. Both L-R or R-L strip flows are handled easily with the automatic built-in gauge bar.

World’s most compact semi-automatic shearwelder

Why Choose Guild

Portable shear welders are a family of one of the world’s most compact shear welders available in semi-automatic and automatic working conditions. Portable shear welders are precise thin gauge machines that are ideally suited for use in roll form lines, coil mill, small tube mill, and stamping presses; and can cut material down to any thickness and width as per the requirement. The shear welders’ portable design allows the use of the machine for multiple line cutting regardless of strip flow, thus bringing down cost to half or one-thirds. There are a variety of portable shear welders available for use in a variety of purposes.

Many of the latest portable shear welders are automated welding and cutting equipment that have features such as pneumatic double blades for precise straight and effective cutting, automatically centralized pneumatic copper mold clamp for accurate and rapid function, precise motor and switch with stable and precise welding gun movement, inverter DC TIG welder to ensure top class welding quality, compact construction, round/square tube makers such as furniture/decoration tubes, roll-forming rack makers such as window slide/ceiling racks and continuous press makers such as silic chip and electronic parts pressing.

Welders such as the PSA 2000 Portable Shearwelder are the most sought after machines because of their design and features. The PSA 2000 contains some standard features such as a tungsten height gauge that ensures a proper setting for the tungsten electrode and a proper weld fit up, with a built-in automatic gauge bar with patented split elevating backup bars. The PSA 2000 also includes properly sized air cylinders that are meant for providing maximum clamping force; as well as the solenoid operated clamping bar to eliminate the need for forward and reverses weld carriage motor relays and weld start limit switch. Some of the other features of PSA 2000 shear welders include a pneumatically powered three-blade shear for distortion free shearing with 2 die spring loaded stripper pads for straight cut, automatic relay to sense that welding arc is correctly established, and step-down transformer, and quick change backup bars.

Other types of shear welders available from Guild International include the VE-10 shear welder, which is a low cost shear welder used to join coils that are 10-inch wide by 0.075-inch thick for use in on stamping lines, roll form lines, and tube mills. The VE shear welder include features such as the automatic built in gauge bar, mounted work light, and automatic weld cycle. The VE-10 shear welders are also equipped with manual lever-arm shears and manual clamping for precision edge cutting and accurate positioning of thin gauge strips. Also included are the DC variable speed carriages and a 225-amp weld rectifier. Adjustable features make the HMA and DMA portable shear welders easy to operate. These shear welders come with a trailing coil, and with automatic welding option at variable-speeds. Also included are reversible shear knives and weld backup bars. The HMA shear welders have hand operated shears and weld clamps, while the DMA shear welder are hydraulically operated. These shear welder can also be custom designed as per the requirement of the customer, with requisite specifications as demanded.