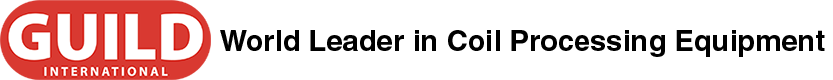

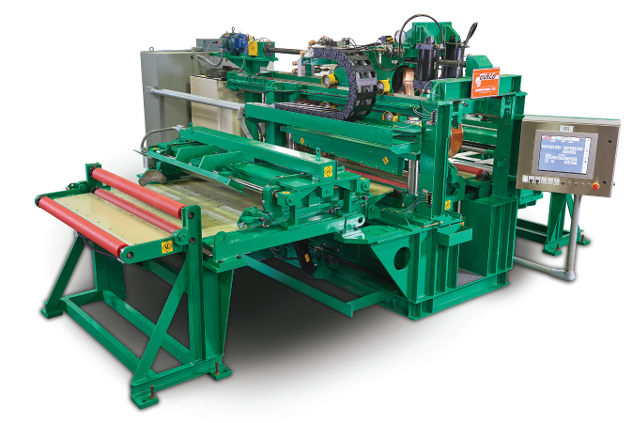

The NB Overlap Resistance Welder™ produces a fast, high strength weld. Units are available with shear and transfer clamps so that the overlap can be kept to a minimum.

NB OVERLAP RESISTANCE WELDER EXCLUSIVE FEATURES:

The NB Overlap Resistance Welder can be used on most materials that range from about 0.075mm (0.003″) up to about 6.5mm (0.250″) thick and any width up to about 2,500mm (100″). The NB Overlap Resistance Welder is a machine that joins two overlapped coil ends together using the resistance welding process. This machine can be used on almost any process line, but is usually found on lines such as:

- Paint

- Leveling

- Annealing

- Galvanizing

- Cleaning

- Polishing

- Plating

- Grinding

Fast, high-strength welds with the NB Overlap Resistance Welder

The welds created with the NB Overlap Resistance Welder are overlap welds created by the use of a weld wheel and a current wheel. Current passes from the wheel through the overlapped strip ends and a weld nugget is formed, joining the ends together. Depending on material and thickness, the welds can be made in either “spot”™ mode or “seam”™ mode. Light gage material uses a steady movement of the weld wheels and a seam is made, whereas when welding thicker material the wheels will quickly stop on the strip and create weld spots. The thickness of the weld is equal to the sum of the strip thicknesses. The amount of overlap that is made can vary depending on options that are purchased, but can be as little as about 10mm (.375”) on light gauge material. Since the weld is made using electrical resistance, the strip ends should be free of rust, scale, and other debris.