The QM Quicklap Seam Welder™ produce very high quality welds that are generally no more than 10% thicker than the parent material. Welds can be made in less than 25 seconds using these welders, depending on strip size.

QMT AND QMM QUICKLAP SEAM WELDERS EXCLUSIVE FEATURES:

The QM Quicklap Seam Welder series includes two (2) machines, depending on your requirements. The QMT is used for higher speed applications and the QMM is used on heavier gage applications. The QM Series Seam Welder joins two (2) coil ends together by resistance welding two slightly overlapped strip ends. The QM Seam Welder is designed for use on either start/stop or continuous lines such as:

- Paint

- Leveling

- Annealing

- Galvanizing

- Cleaning

- Tinning

- Plating

- Inspection

- Coil Buildup

QMM and QMT Quicklap Seam Welders for welds no thicker than 10% of parent material

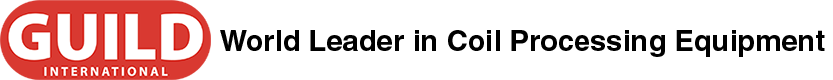

Why Choose Guild

The weld created by the QM series seam welder is an overlap resistance weld. The two coil ends are slightly overlapped and the weld wheels, one on the top and one on the bottom, roll across the overlapped ends to make the weld. Then hardened planish rolls, again one on the top and one on the bottom, follow the weld wheels, and the result is a very fast, flat, and strong weld. Welds created using this machine are usually nearly as strong as the parent material. An optional induction annealer can also be placed on the machine to post-anneal the weld during the same pass as welding and planishing.

The QMT and QMM can shear, weld, and planish material ranging from about 0.1mm (0.004″) up to about 3.0mm (0.125″) thick, and as wide as necessary. Recent machines have been used for strip up to 1,900mm (76″) wide. Any weldable material can be joined on these machines.

The QM Quicklap Seam Welder is actually a resistance welder meant for use with cold rolled strips. The QM Quicklap Seam Welders, available in two major varieties are meant for use in very high quality and delicate welding processes where the welded material is generally not more than 10% thicker than the thickness of the parent material. The QM Quicklap Seam Welders are highly efficient welding machines that can weld materials in less than half a minute, depending on strip size. The QM Quicklap Seam Welders have unique features that distinguishes them from other welding systems. The QMT Quicklap Seam Welder is meant for use in higher speed applications; while the QMM Quicklap Seam Welder is meant for used in heavier gage applications. The QM Series Seam Welders have been designed for use in either start to stop or in continuous line operations such as paint, galvanizing, plating, leveling, cleaning, inspection, annealing, tinning, and coil buildup. The welding created by QM series is an overlap resistance weld.

The QM Quicklap Seam Welder is ideally suited to join two coil ends together by resistance welding two slightly overlapped strip ends.

In this process the weld wheels positioned on top and bottom, seamlessly roll across the overlapped ends to weld the materials. After this is done, the hardened planish rolls one on the top and one on the bottom, follow the weld wheels, and this results in a very fast, as well as flat and strong weld. The welding created using these machines are usually as strong as the parent material. An optional induction annealer is also available with the QM Series Seam Welders, which can be placed on the machines to post-anneal the welding in just the same manner as is done while doing welding and planishing (planishing means to smoothen metal by using rolling or hammering mechanism). The specialty of QMT and QMM Series Seam Welders is that both are capable of shearing, welding, and planishing alloys and metals that are available in a variety of thicknesses, ranging from 0.004-inches to up to about 0.125-inch thickness. The QM Series Seam Welders are capable of seam welding metals and alloys as wide as possible depending on the requirement.

With the advancement in technology, the new types of QM Quicklap Seam Welder can be used to strip metals and alloys with width of up to 76-inches.

This huge width allows the QM Series Seam Welders to weld any sort of weldable metals, alloys or other types of weldable materials. Another type of resistance welder is the NB Overlap Resistance Seam Welder, which is also meant for use in a fast and high strength welding process. The NB Overlap Resistance Seam Welders are available with shear and transfer clamps, so that time spent on overlapping of strip ends can be kept to a bare minimum. The NB Overlap Resistance Seam Welders can be used to weld a variety of metals and alloys with varied thickness ranging from 0.003-inch to about 0.250-inches and width of up to 100-inches. Similar to QM Series Seam Welders, the NB Overlap Resistance Seam Welders joins 2 overlapped coil ends together using resistance welding process, and as such can be used in the same processes as the QM Series Seam Welders.