Laser Welders

MEL Laser Welder

Applications

Designed for use on start/stop lines or continuous lines such as stamping lines, specialty tube, coil buildup, pickling, galvanizing and annealing lines

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Weld Power Source

Laser

Weld Appearance

Thickness Range

(0.38 – 10mm)

Width Range

(457–2032mm)

Automation

Fully automatic

GLS Laser Welder

Applications

Designed for use on start/stop lines or continuous lines such as stamping lines, specialty tube, coil buildup, pickling, galvanizing and annealing lines

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Weld Power Source

Laser

Weld Appearance

Thickness Range

.020” –.250”

(0.50 – 6.5mm)

Width Range

24”–76”

(600–1930mm)

Automation

Fully automatic

LHMA Laser Welder

Applications

Designed for use on start/stop lines or continuous lines such as traverse wind, cable lines, stamping lines, specialty tube, coil buildup, and thin strip lines

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Weld Power Source

Laser

Weld Appearance

Thickness Range

(0.08–1mm)

Width Range

(5–108mm)

Automation

Semi-automatic

Arc Welders

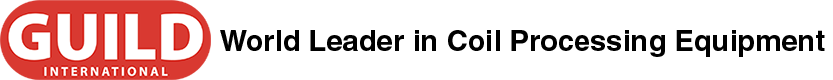

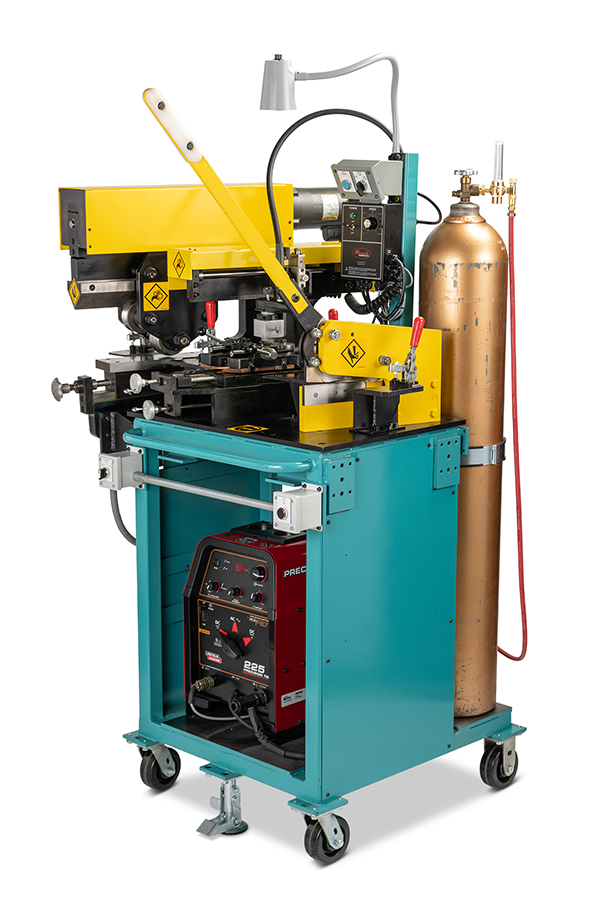

PSA 2000 Portable Shearwelder

Applications

Ideal for small tube mill, roll form lines, and stamping presses

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Weld Power Source

TIG

Weld Appearance

Thickness Range

(0.25–3.5mm)

Width Range

(12–508mm)

Automation

Semi-automatic

VE-10 Shearwelder

Applications

Designed for use on stamping lines, roll form lines, and tube mills

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Weld Power Source

TIG

Weld Appearance

Thickness Range

(0.25–2mm)

Width Range

(12–381mm)

Automation

Semi-automatic

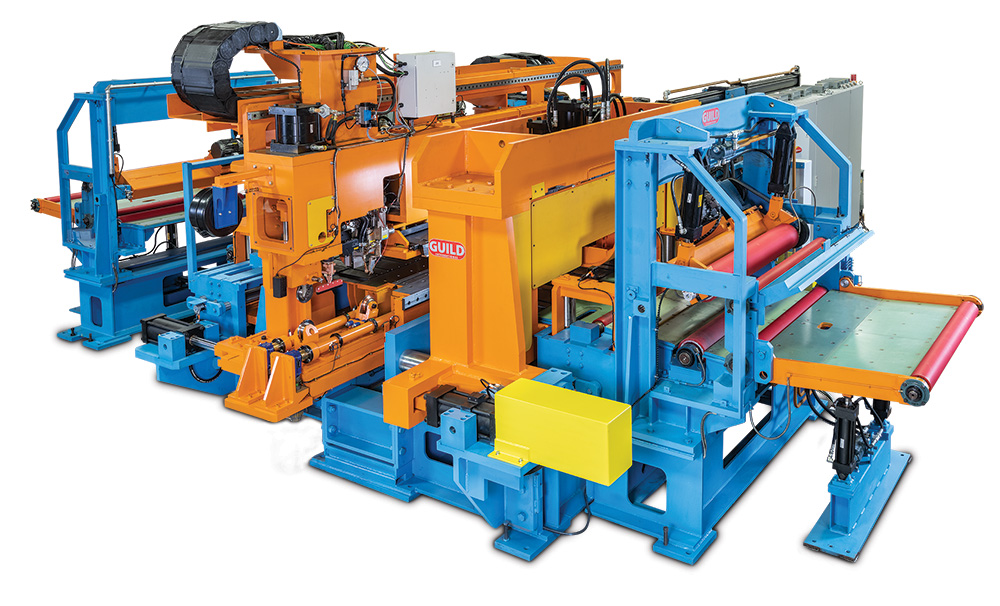

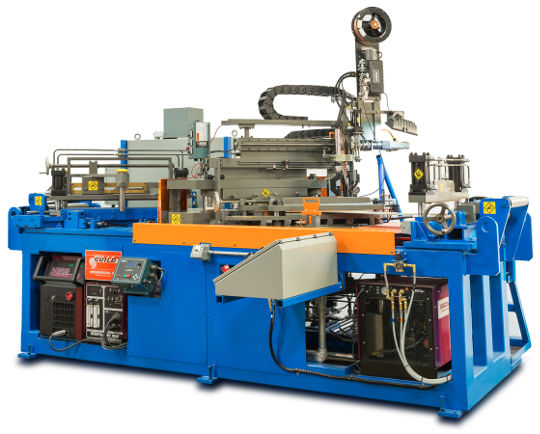

ME/MES Zipwelders

Applications

ME Zipwelder: Designed for use on stamping, roll form, tube mills, coil buildup, rolling, galvanizing, slitting, annealing and pickling lines.

MES Zipwelder: Designed for most continuous and start/stop lines, such as APL, CGL, CBL, where the tail end is fixed.

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Weld Power Source

TIG, MIG, Plasma, Laser

Weld Appearance

Thickness Range

.006”–.750”

(0.15–19mm)

MES Zipwelder

.006”–.300”

(0.15–7.6mm)

Width Range

(25–1829mm)

Automation

Fully automatic or semi-automatic

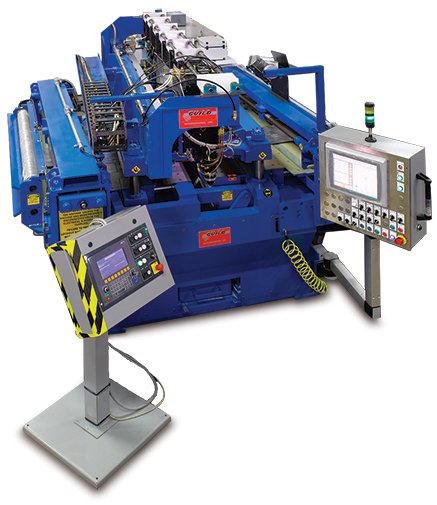

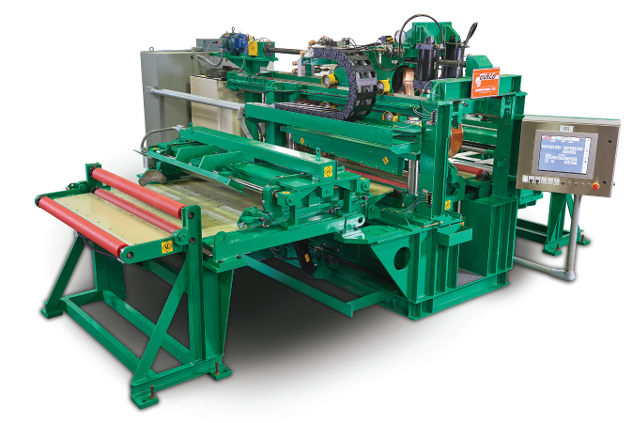

RCM Zipwelders

Applications

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Weld Power Source

TIG, MIG, Plasma, Laser

Weld Appearance

Thickness Range

(0.45–25mm)

Width Range

(508–2032mm)

Automation

Fully automatic

DMI Shearwelders

Applications

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Weld Power Source

TIG, MIG, Plasma, Laser

Weld Appearance

Thickness Range

(10–25mm)

Width Range

(152–2160mm)

Automation

Fully automatic or semi-automatic

HMA/DMA Shearwelders

Applications

Ideal for thin-gauge strip processing lines where coil ends can be positioned manually from the shear to the weld station

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Weld Power Source

TIG, MIG, Plasma, Laser

Weld Appearance

Thickness Range

.005”–.160”

(0.127–4mm)

Width Range

(3.2–508mm)

Automation

Semi-automatic

Resistance Welders

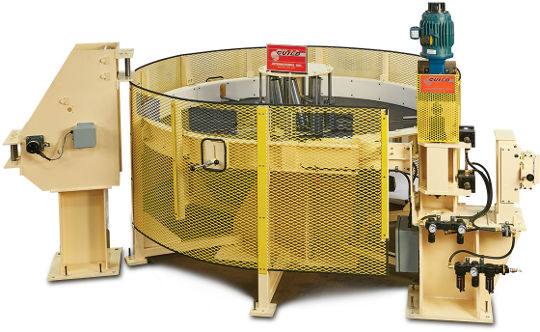

NB Overlap Resistance Welder

Applications

Materials

Steel, stainless steel, silicon steel, aluminum, titanium, and special alloys

Weld Power Source

Resistance

Weld Appearance

Thickness Range

(0.08–6.3mm)

Width Range

(254–2540mm)

Automation

Fully automatic

QM Quicklap Seam Welder

Applications

Designed for use on start/stop lines or continuous lines such as paint, leveling, annealing, galvanizing, cleaning, tinning, plating, inspection

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Weld Power Source

Resistance

Weld Appearance

Thickness Range

(0.10–3.2mm)

Width Range

(508–1930mm)

Automation

Fully automatic

Tube Mill Entry Machines

UNC Uncoiler

Applications

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Capacity

(2250–18,150 kg)

Width Range

(50–1000 mm)

Automation

Fully automatic

SF Speed Funnel

Applications

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Width Range

(1000 mm)

Automation

Fully automatic

FLT Flattener

Applications

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Width Range

(1000 mm)

Automation

Fully automatic

Accumulators

Applications

Materials

Steel, stainless steel, silicon steel, copper, brass, aluminum, titanium, and special alloys

Speeds

(15–300+ MPM)

Thickness Range

(0.25–20 mm)

Automation

Fully automatic